DRY POWDER RIGS

Provides automatic batching of dry powder flocculant with water for consistent solution strength.

ABOUT DRY POWDER POLYMER MAKEDOWN SYSTEM

How They Work

The Fusion Works Dry Powder Polymer Makedown System automatically batches dry powder flocculant with water. This produces a homogeneous, activated polymer solution with a consistent solution strength and outstanding characteristics, ensuring full-length polymer chains to maximise process efficacy.

Product Capabilities

The system is equipped with a high-quality water booster pump to ensure correct pressure and flow for optimum dry powder dispersion. All our systems are tested and commissioned before dispatch.

Product Benefits

- User-friendly and as maintenance-free as possible.

- Wet tested before dispatch

- Optimum inversion without polymer chain harm

- Designed to make-down flocculant and coagulant in solutions 0.5%, 1% + 1.5%

- Changeable polymer types

- Adjustable dosing rates

- Dosing systems will maintain the set polymer dose rate even when incoming water flows and pressures fluctuate.

- Drawdown columns for simple calibration and commissioning.

- The integrated floc tube design extends contact and reaction time to ensure a high level of coagulation and flocculation.

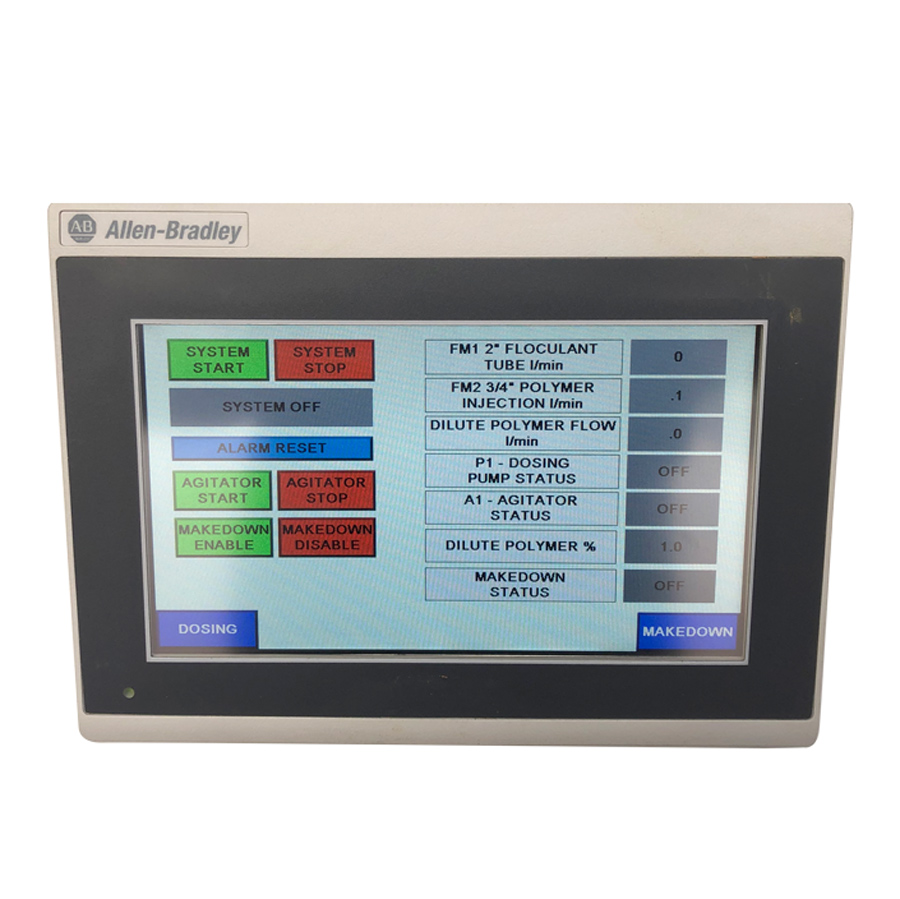

- PLC touch screen included for easy control

Dry Powder Rig Setup

Step One:

Choose the relevant polymer for the application.

Step Two:

Conduct a jar test to determine the solution strength and dose rate in ppm.

Step Three:

Simply enter the results via the touchscreen.

The Rig in Action:

The system will automatically start making-down a quality homogeneous polymer solution and start dosing the wastewater floc tube at the dose rate determined during jar testing.

Dry Powder Polymer Setup Rigs are scalable and can efficiently function in small or large plants, as the interface and controls remain the same regardless of the system scale.

An Overview of Dry Powder Polymers

Dry powder polymers and other flocculants are used to coagulate very small suspended solids into larger curds or flocs that are big enough to be removed efficiently from water.

Common Issues with Dry Powder Polymers

Choosing a suitable polymer for your wastewater plant is only half the battle.

Assuming all operational parameters are well managed, your plant may underperform if the polymer make-down and dosing system are inadequate. Improper dispersion of dry powder can lead to inconsistent and substandard polymer solutions.

Mixing and diluting dry powder polymers with water is critical for optimal performance. Incorrect dispersion can result in either too weak or too concentrated solutions, leading to equipment downtime, damage and costly repairs.

Unfortunately, poor dispersion cannot be remedied through mixing alone. Over-shearing can also degrade polymer integrity, reducing its effectiveness in wastewater treatment.

CUSTOM PRODUCT QUOTE REQUEST

Contact us for more information regarding our custom products and solutions, or simply request a quote:

ABOUT

FUSION WORKS CUSTOM FABRICATED PRODUCTS

A complete project package from process design and engineering, to fabrication and installation

Bespoke Solutions

Custom products tailored to your specifications and needs

Local Fabrication

Designed, engineered and fabricated locally in Kensington (VIC)

Broad Capabilities

An experienced team of knowledgable problem solvers

Expert Execution

Professional onsite delivery, installation and ongoing maintenance